Let’s examine some of the hazards your team may encounter while working on extension ladders and discuss what employers and workers can do to reduce injuries.

Be Careful. Extension Ladders Aren’t Self Supporting

An extension ladder, often called “portable ladders,” usually have two sections that operate in brackets or guides allowing for adjustable lengths. Because extension ladders are not self-supporting they require a stable structure that can withstand the intended load.

How to Get the Job Done Safely? PLAN!

- Ensure your ladder can sustain at least four times the maximum intended load. How to ensure you have the right ladder? To determine this, add your weight plus the weight of your load. It is important to not exceed the load rating and always include the weight of all tools, materials, and equipment.

- Be sure to visually inspect all extension ladders before use for any defects such as missing rungs, bolts, cleats, screws, and loose components. Where a ladder has these or other defects, it must be immediately marked as defective or tagged with “Do Not Use” or similar language.

- Allow sufficient room to step off the ladder safely. Keep the area around the bottom and the top of the ladder clear of equipment, materials, and tools. If access is obstructed, secure the top of the ladder to a rigid support that will not deflect, and add a grasping device to allow workers safe access.

- Setting the ladder at the proper angle is very important. When a ladder is leaned against a wall, the bottom of the ladder should be one-quarter of the ladder’s working length away from the wall. For access to an elevated work surface, extend the top of the ladder three feet above that surface or secure the ladder at its top.

- Another best practice is to survey the area for potential hazards, such as energized overhead power lines. If you are working near powerlines all ladders and other tools should be at least 10 feet away. When working near energized electrical equipment, there are ladders that may have nonconductive side rails to ensure the worker is not exposed.

- If a ladder is ever placed in front of a door, always be sure to block off the door.

Selecting the Correct Ladder

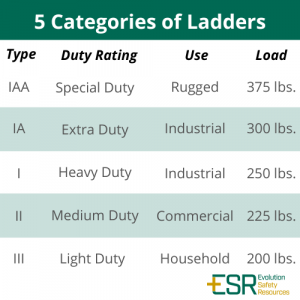

It is best practice to select a ladder based on the expected load capacity (duty rating), the type of work to be done, and the correct height. There are five categories of ladder duty ratings.

Safe Ladder Use—DO:

- When climbing a ladder maintain a 3-point contact. What is that? Using two hands and a foot, or two feet and a hand when climbing or descending a ladder.

- Always face the ladder when climbing up or descending.

- Keep your body inside the side rails.

- Avoid tipping the ladder over sideways or causing the ladder base to slide out.

- If you have to carry tools be sure to use a tool belt. Raising tools up using a hand line is also another safe option. Never carry tools in your hands while climbing up/down a ladder.

- Be sure to extend the top of the ladder three feet above the landing.

- Keep ladders free of any slippery materials.

Safe Ladder Use—DO NOT:

- Place a ladder on boxes, barrels, or any unstable base.

- Use a ladder on soft ground or unstable footing.

- Exceed the ladder’s maximum load rating.

- Tie two ladders together to make them longer.

- Ignore nearby overhead power lines.

- Move or shift a ladder with a person or equipment on the ladder.

- Lean out beyond the ladder’s side rails.

- Use an extension ladder horizontally like a platform.

If you need assistance understanding the OSHA standards or you’re interested in learning about the steps we take to ensure workplace safety and compliance, let’s get the conversation started today. Our experts at ESR are ready and available to help. We offer free consultations and will develop complimentary improvement plans.